Plastic injection molding has become one of the most essential manufacturing processes across global industries. From medical devices and aerospace components to industrial equipment, electronics, and consumer goods, companies rely on molding solutions that deliver accuracy, consistency, and scalability. As demand grows for tighter tolerances, specialized materials, and more complex geometries, manufacturers increasingly partner with expert firms capable of meeting these advanced production challenges. One standout example is Plastic Molded Concepts, a leading plastic injection molding company offering both horizontal and vertical molding services designed to produce high-quality, precision components for diverse applications.

This article explores the evolving landscape of plastic injection molding solutions—and why companies like Plastic Molded Concepts are at the forefront of next-generation manufacturing.

Why Plastic Injection Molding Remains the Gold Standard in Manufacturing

Despite the rise of alternative processes like additive manufacturing, plastic injection molding continues to dominate high-volume production for several reasons:

1. Superior Precision and Repeatability

Injection molding can consistently produce identical parts with tight dimensional tolerances, making it ideal for complex, performance-critical assemblies.

2. Exceptional Production Efficiency

Once the mold is created, the cycle times are rapid, allowing manufacturers to scale output without sacrificing quality.

3. Material Versatility

From high-impact engineering resins to medical-grade polymers and specialized composites, injection molding works with a wide range of materials tailored to specific performance needs.

4. Cost-effective at Scale

For medium to high-volume runs, injection molding offers the best cost-per-part ratio compared to other manufacturing processes.

5. Ability to Produce Complex Geometries

Modern mold-making technologies allow for intricate details, undercuts, threaded features, multi-material components, and insert molding.

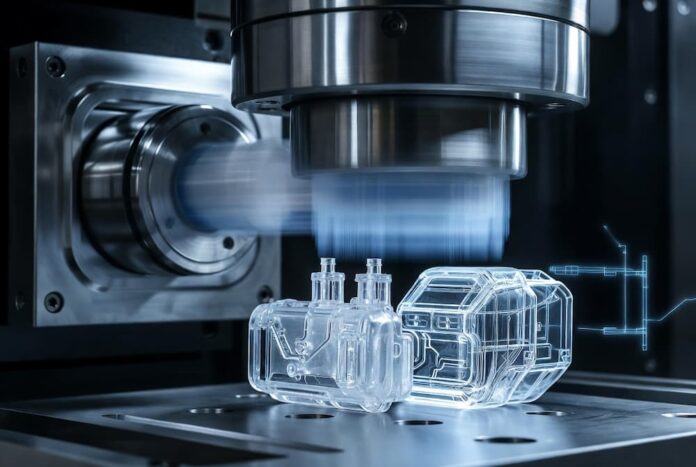

Key Innovations Driving Today’s Injection Molding Solutions

Modern molding is far more advanced than it was just a decade ago. The integration of automation, advanced controls, and innovative tooling has transformed production capabilities.

Automated Production Cells

Robotic handling removes inefficiencies, improves cycle times, and ensures consistent part quality.

Scientific Molding Techniques

Precise control over pressure, temperature, viscosity, and cooling leads to dramatically improved part performance and fewer defects.

In-mold Sensors and Monitoring

Real-time data collection allows engineers to detect and correct issues before they affect production.

Advanced Mold Materials and Coatings

Durable steel alloys and specialized coatings extend mold life and support high-heat or abrasive materials.

Micro-Molding Capabilities

For medical and aerospace applications, manufacturers are now able to produce extremely small, highly detailed components with remarkable precision.

Plastic Molded Concepts: A Leader in Precision Molding Across Industries

Among the companies defining excellence in modern injection molding, Plastic Molded Concepts stands out for its technical expertise, industry knowledge, and ability to handle complex manufacturing challenges. Their reputation as a specialized plastic injection molding company comes from decades of experience serving industries that demand some of the most precise molded components on the market.

A Unique Strength: Both Horizontal and Vertical Molding Capabilities

While many molding companies specialize in only one type of press, Plastic Molded Concepts offers both:

Horizontal Injection Molding

- Ideal for high-volume production

- Supports multi-cavity molds

- Enables the creation of complex, detailed geometries

- Provides efficient, repeatable manufacturing for large runs

Horizontal presses are the backbone of traditional injection molding and are perfect for components used in industrial equipment, consumer products, and technical assemblies.

Vertical Injection Molding

- Perfect for insert molding

- Allows gravity-assisted placement

- Enables overmolding of metal, electronics, or other components

- Offers unmatched precision for specialty parts

Vertical molding is essential for applications where plastic must be molded around another object, such as bushings, connectors, sensors, threaded inserts, and hybrid components.

This dual capability allows Plastic Molded Concepts to accommodate an extensive variety of part designs and industry requirements — giving clients a level of flexibility not always available with typical molders.

Industries That Benefit from Advanced Injection Molding Solutions

Plastic Molded Concepts and companies like it support a broad range of sectors where reliability and precision are non-negotiable.

Medical & Life Sciences

- Diagnostic equipment components

- Surgical tool housings

- Laboratory consumables

- Clean-room compliant parts

High-performance medical plastics require exact tolerances and strict quality control — areas where expert molders excel.

Aerospace & Defense

- Lightweight structural components

- High-temperature polymer parts

- Electronics housings

- Engineered assemblies requiring insert molding

These industries depend on resin expertise and flawless production repeatability.

Industrial & Commercial Equipment

- Gears, housings, enclosures

- Custom fasteners and fittings

- Wear-resistant polymer components

Injection molding supports both durability and scalability.

Electronics & Technology

- Connectors

- Enclosures

- Precision overmolded components

Vertical molding is especially valuable here.

Automotive & Transportation

- Interior components

- Sensor housings

- Under-the-hood high-heat parts

Engineering-grade plastics provide strength while reducing weight.

Why Companies Choose Plastic Molded Concepts

Organizations often partner with Plastic Molded Concepts because of their:

1. Deep Material Expertise

Their team understands how different polymers behave under heat, pressure, and long-term use, allowing them to recommend materials that meet each project’s functional requirements.

2. Ability to Tackle Difficult or Highly Technical Jobs

Many of their clients approach them after other molders decline a project due to complexity. PMC’s engineering-driven approach shines here.

3. Precision Manufacturing at Scale

Through scientific molding methods and advanced process control, they ensure part-to-part consistency across every production run.

4. Tailored Solutions for Each Industry

Their vertical and horizontal molding services allow for exceptional versatility.

5. Commitment to Quality and Compliance

They follow rigorous quality standards and documented workflows to ensure every component meets regulatory and performance requirements.

The Future of Plastic Injection Molding

As technology continues to evolve, the next-generation of injection molding will be shaped by:

- AI-driven process optimization

- Fully automated production cells

- More sustainable materials and bio-polymers

- Improved energy efficiency

- Enhanced mold cooling technologies

- 3D-printed tooling for rapid iteration

Companies that embrace scientific molding, automation, and advanced materials — like Plastic Molded Concepts — are positioned to lead the industry into this future.

Final Thoughts

Plastic injection molding remains a foundational manufacturing process due to its precision, efficiency, and scalability. Organizations across medical, aerospace, industrial, and technology sectors rely on high-performance molding solutions to meet increasingly strict requirements. With expertise in both horizontal and vertical injection molding, Plastic Molded Concepts delivers the engineering depth and manufacturing reliability needed to produce complex, high-quality components for the most demanding applications.